Page last updated on February 19, 2026 at 1:40 pm

Plan Review:

All documents and plans should be submitted through the City's Civic Access Portal to begin the review process. Projects must also be submitted to the Monroe County Building department through OpenGov to obtain appropriate permits.

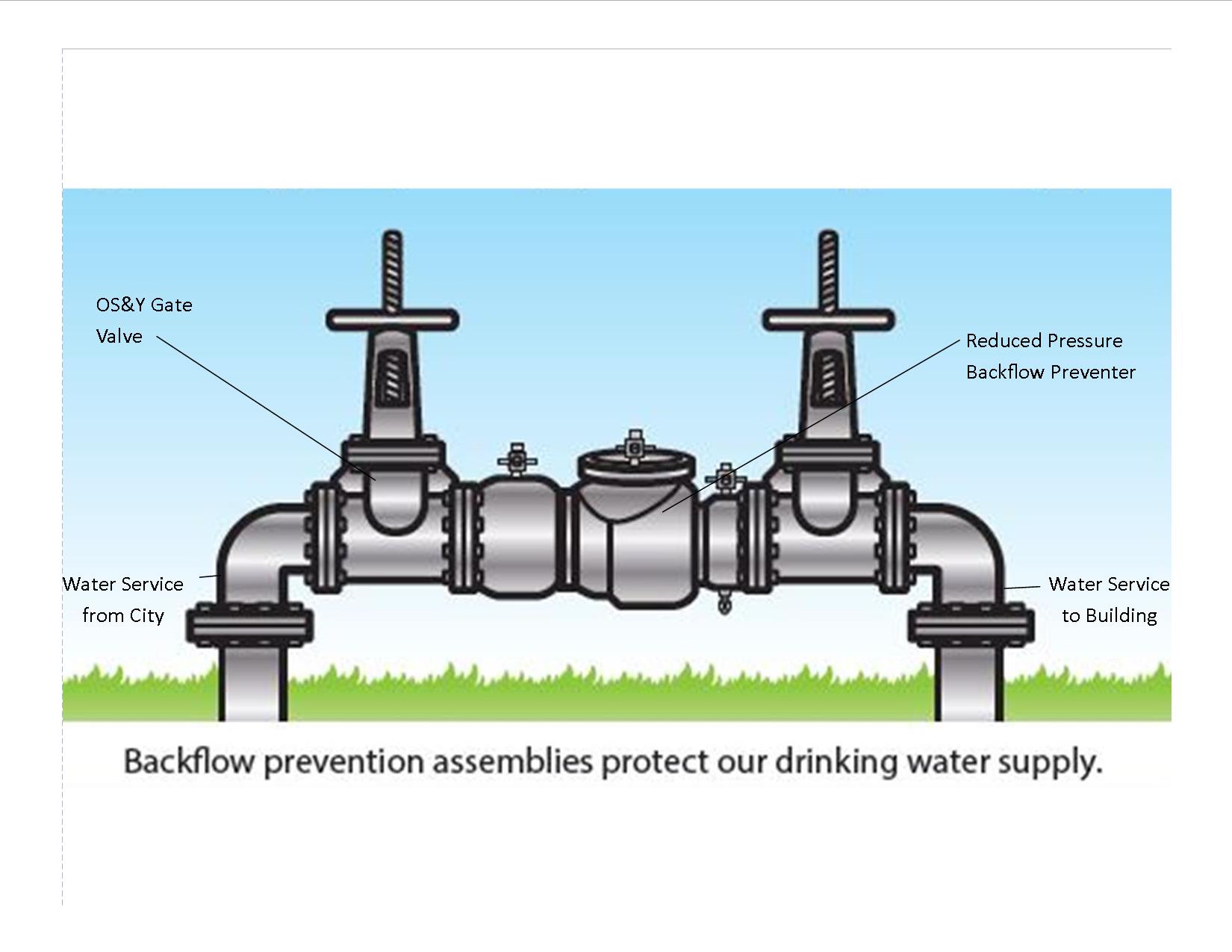

Refer to the Backflow Prevention section in the CBU Design Standards Guidelines Manual for all requirements to be included on your plumbing plan submittal (domestic water / fireline / irrigation). Also refer to the Standard Details section of our website to download copies of CBU's details to include on your plans.

Does My Project Need a Backflow Preventer?

A reduced pressure principle assembly is recommended on all commercial customer service lines and multifamily service lines. An approved backflow prevention assembly is required on all customer service lines if the building will house a designated cross connection hazard as specified by 327 IAC 8-10-4 or as determined by CBU.

The following types of facilities commonly require backflow prevention:

- Irrigation Systems

- Fire Sprinkler Systems

- Domestic Water Systems of:

- Restaurants containing carbonated beverage dispensers

- Breweries

- Car Washes

- Laboratories

- Medical Buildings

- Manufacturers (pharmaceuticals, paper products, metals & plastics, etc.)

- Dry Cleaners

What Type of Backflow Preventer Do I Need?

The type of backflow preventer required is dependent on the degree of hazard the customer's water system poses to the public water supply. Requirements are detailed in CBU's Construction Specifications and Standard Details.

General Requirements:

Irrigation Systems require either a Pressure Vacuum Breaker (PVB) or Reduced Pressure Backflow Preventer (RP) depending on whether the system will be subject to backpressure. If sprinkler heads are located at a higher elevation than the backflow preventer, if a booster pump is required, or if multiple service lines are required, an RP is necessary. If no conditions that may cause backpressure are present, a PVB may be installed.

Fire Sprinkler Systems typically require a Double Check Detector Assembly (DCDA). On systems that have a combination fire & domestic meter installed upstream, a regular Double Check Valve (DC) may be substituted. For systems with chemical additives such as antifreeze, a reduced pressure backflow preventer or reduced pressure detector assembly is required.

Domestic Water Systems typically require a Reduced Pressure Backflow Preventer to protect the public water supply from the variety of hazards posed by commercial facilities.

CBU requires that all models of backflow preventer installed on its water system are approved by the University of Southern California's Foundation for Cross-Connection Control and Hydraulic Research (USC), and are compliant with American Water Works Association standards C510 and C511, if applicable. USC maintains a list of approved backflow preventers. These approvals are also commonly available on the specification sheets of most of the major backflow preventer manufacturers. All backflow preventers installed within CBU's water system must be done so in an orientation and configuration approved by USC.

- When specifying a model of reduced pressure backflow preventer for domestic use, it is also important to select a model that is certified as lead-free. Some models are manufactured with leaded brass that are only legal for installation on nonpotable systems.

Where Does the Backflow Preventer Need to Be Installed?

- Irrigation Systems: Irrigation backflow preventers are required to be installed before any branching of the lines of the system, at minimum 12 inches above ground.

- Fire Sprinkler Systems: CBU requires fireline backflow preventers to be installed outdoors in a meter vault if the fire riser is 100 feet or more from the connection to the domestic branch. If a vault is required, it must contain a sump pump or gravity drain pipe to prevent flooding of the backflow preventer. If this distance is under 100 feet, the backflow preventer may be installed in the riser room.

- Domestic Water Systems: Domestic backflow preventers are required to be installed immediately after the water service line enters the building, before any branching of the system. Reduced pressure backflow preventers should also be located above a sanitary sewer drain to capture water from the relief valve. These devices are also required to be installed above ground-grade.

Can a Reduced Pressure Backflow Preventer Be Installed Vertically?

- Backflow preventers must be installed in the installation orientation for which they were designed and approved (vertical, horizontal etc.).

- There are few RP models approved by USC that are approved for vertical installation, but they do exist in certain sizes. USC's list of approved backflow preventers can be filtered to narrow down which models and sizes of RP are approved for vertical installation.

What Do I Need to Include in my Submission?

- Plan submittals must include the location, make and model number of backflow prevention device, and connections to all downstream fixtures. If you would like to see example diagrams, please contact us at [email protected].

- Plan submittals should also include the appropriate CBU Standard Details, which are available on our Standard Details webpage.

- Please add a note to the plans that all backflow devices must be tested upon installation and have results submitted to trackmybackflow.com.

Inspection Requirements:

- Once any new backflow preventer has been installed, it must be inspected by CBU to confirm the device meets all installation standards. This inspection must take place prior to project closeout. Contact the Environmental Program Coordinator at 812-349-3633 or [email protected] to schedule an inspection.

Additional information about our Backflow Prevention Program, standard details, approved devices, installation or inspection requirements, device testing requirements, and submission of the testing reports is also available on our website. Or contact our Environmental Program Coordinator at 812-349-3633, or by email: [email protected].